Problem:

A large, mixed use building wanted to improve the cellular network performance in their building. They hired a cellular engineering company to design the new network(s), but they did not have usable floor plans, or a baseline analysis of current cellular performance. The engineering company needed current plans, information about wall materials, as well as a complete cellular network analysis in order to effectively design a solution.

Summary:

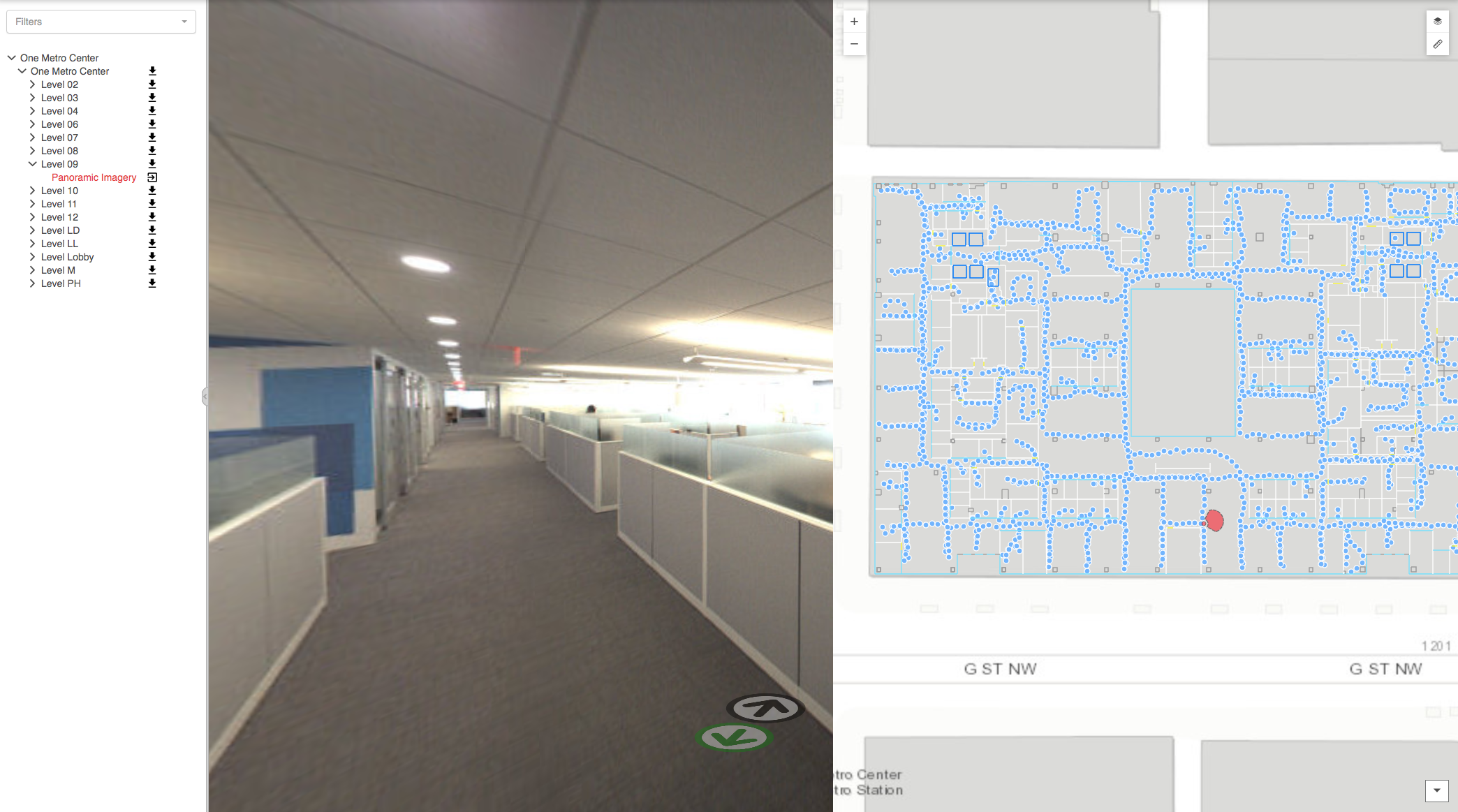

IndoorVu was able to simultaneously collect data for both the Cellular network and building model requirements. The deliverables included measurements from all 4 main US carriers, 360 imagery and custom floor plans designed to integrate into the network design tools used by the engineering company. IndoorVu also provided updated floor plans and imagery to the building owner for use in their existing Facilities Management and Space Planning tools.

Result:

The Engineering company was provided with three main datasets that saved them time and money during the design and construction process. 1) comprehensive data on the existing cellular network conditions needed to design a new optimal indoor network. 2) accurate and formatted floor plan data that could import directly into their design software, saving them significant time modeling it themselves. 3) 360 degree imagery for all parts of the building, both tenant space as well as technical closets and storage areas, saving them a number of site visits and allowing them to make an accurate construction plan remotely.

The building owner benefited as well, with getting updated floor plans and imagery they used for other operational projects (ie: fire system upgrades, space planning and security enhancements).

The time to deliver, completeness and flexibility of data provided by IndoorVu provided direct value and cost savings to the cellular network project, and indirect benefit and operational efficiency to the building owner.